TPI 1normal circular pitch. Check out this diagram that showcases the variety of knurling tools for different applications.

Mechanical Engineering How To Define Knurl On Drawing Engineering Stack Exchange

Blank Diameter Teeth part Diametral Pitch American Standard ANSI B946-1984 describes the diametral pitch knurl system.

. Before we get on with Surface Finish Symbols lets understand how Surface Finish is defined. It seems that there are at least a few different techniques assign an appearance on the part create an area hatch on the drawing and fully model the knurl but which. True knurling in AutoCAD.

Knurl Feature in A Drawing File I have created a Chuck Cap of which applied a knurled material to the surface and i am not able to show any visual representation for that. There is no exact definition for coarse medium and fine pitch knurling. Make sure both wheels spin at the exact same time when hand-jogging up to the material make sure the material diameter is proper for the pitch of the wheels you are using feed in over and rapid out.

CI By Chris Italiano 101911. Dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. I am only able to include a text leader telling that the surface is knurled rather than showing visualy.

Keep the profile sketch as simple as possible. Create a sketch on a plane where you are able to project the region onto your surfaces. Except for these 3 TPIs Accu-Trak and all other current knurl manufacturers produce their diagonal and diamond knurling wheels to the Normal TPI.

Learning to read blueprints can be hard. Chamfers can also be specified by giving both legs of the chamfer such as. To add the callout.

For Inventor 2012 as far as I know Right click on the surface you want knurl click on properties you should get a face properties dialog box hit the face color style flyout arrow and a metal knurled option should be there. Explain why a knurled pattern is needed. Best practices for knurled parts.

This is a Class III tolerance in accordance with ANSI B946 and applies to straight knurling only. KNURLUNG TOOLS AND KNURLING WHEELS QUESTIONS. By choosing proper modeling parameters you can influence position orientation depth and sizescale of the dents.

If no angle is given the chamfer is assumed to be at 45 degrees. For a knurled surface of turning knobs. The formula is as follows.

3 lines forming a triangle with the top of the triangle well outside of the handle diameter. In my case I used a plane along the axis of my cylinder. How do you recommend creating a knurled surface on a part and then indicating the knurl on the parts drawing.

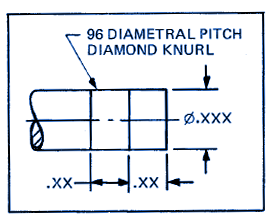

PITCH 8 RAISED DIAMOND KNURL OR 96 DP RAISED DIAMON KNURL ALL AROUND The former gives the actual pitch the second is how many peaks around the diameter DP diametral pitch per ASME Y1438-1999. ANSIASME B946 is the inch-knurling standard. Posted January 17 2013.

To make your knurling come out properly with no double tracking you need to select the blank diameter of your stock to match the pitch of the knurl. ANSI Standard Knurls and Knurling. The standard knurl wheel has a sharp corner on the leading edge which makes the wheel ideal for heavy loading.

Engineering prints call out a great many things in their attempt to make sure the part that gets made matches the designers intent. Using notes and diagrams explain how the process of knurling is carried out. All of the basic components of an engineering drawing are detailed below with links throughout to give you more info on each subject.

Chamfer all edges 025 x 025. Choose Insert Curve Split Line. The wrong blank diameter can cause the knurls to double track giving a pattern finer than the knurl was designed to produce one thats generally unsatisfactory.

CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE. Draw a piece of equipment or a tool that has a knurled pattern. Diametral pitch knurls are designed to track uniformly on fractional size stock up to 1 in multiples of 132 or 164.

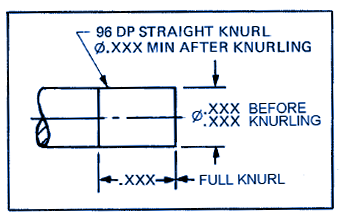

Knurls for press fits are called out by type pitch axial length diameter before knurling and should include the minimum diameter after knurling. Double wheel knurl tool. The pointer changes to when it is over a silhouette edge of a cosmetic thread.

On an actual drawing this translates to a note or call out along the lines of either. The knurled area will be slight larger than other diametersdiamon shaped pattern. Then dimension them as required to define the knurled region.

Thats why weve broken down the process into bite size chunks. Extend the Helix on the left side a little longer to make sure it breaks out on the chamfer 2. How should we do itThere are so many legends about the operationIn this episode Ill try to demystify the process with a logical appr.

You use the Smart Dimension tool to add the callout in a side view or section view of the external thread. If that is the callout on a drawing you have some leeway on either side of what is shown above. For this reason it may not be necessary for manufacturing purposes to model the knurling explicitly in CAD- many times a simple callout on a.

Knurling can produce different types of patterns. In practice knurling is achieved by pressing a dedicated knurling tool into the rotating workpiece. Sketch two lines that intersect the edges of the cylinder.

Click Smart Dimension DimensionsRelations toolbar or Tools Dimensions Smart. June 9 2021 by Brandon Fowler. Select the two silhouette edges of the cosmetic thread.

Some popular knurl patterns are straight diagonal and diamond. Beginners Guide to Blueprint Reading. Aside from dimensions and tolerances another important callout is Surface Finish.

The following table gives standardized diameter pitches and dimensional relationships when producing straight diagonal and diamond knurling on cylindrical surfaces having teeth of uniform pitch parallel to the cylinder axis or at a helix angle not exceeding 45 degrees with the work axis. Using the following procedure you can model a true 3D diamond knurling in AutoCAD - eg.

Mechanical Engineering How To Define Knurl On Drawing Engineering Stack Exchange

Dimensioning Knurled Features Drawings Engineering Reference Tools

Dimensioning Knurled Features Drawings Engineering Reference Tools

Print Reading For Industry 9th Edition Page 207 207 Of 523

Add Knurling As A Surface For 2d Drawings Autodesk Community

Solidworks Knurl Pattern In Drawings Youtube

Add Knurling As A Surface For 2d Drawings Autodesk Community

Mechanical Engineering How To Define Knurl On Drawing Engineering Stack Exchange

0 komentar

Posting Komentar