Selection of stream temperature specifications. This presentation focuses on thermal and hydraulic design of shell and tube heat exchangers Ford Bacon Davis LLC 19.

Excel Calculations Tema Type E Heat Exchanger Design

Check calculate the cooling load from core length.

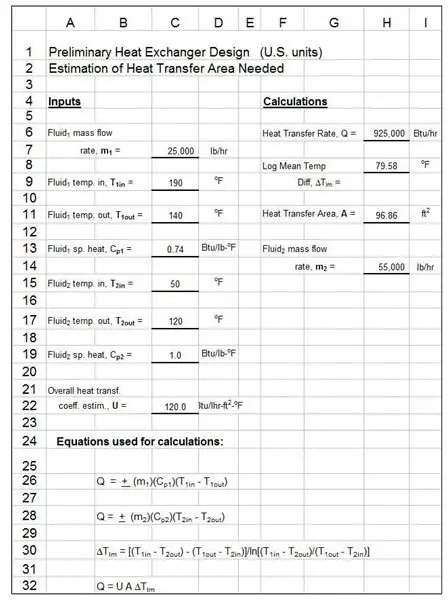

. Calculation of ST heat exchanger area sizing. Tube OD BWG Tube ID d Tube Length L Area of one tube Cross sectional area of tube. Heat exchanger calculations and design with excel.

Shell and tube heat exchanger design is an iterative process which goes through the following steps. Step wise Procedure for Calculation. Extension to other exchanger types requires new equations.

No guidance is given on how to generate these equations. It is required to define mass rate of hot fluid. Pressure losses in shell and tube heat exchangers tube shell sides.

Shell and Tube Exchanger Sizing Calculation Excel Template. These templates use SI. Very easy to use and user friendly.

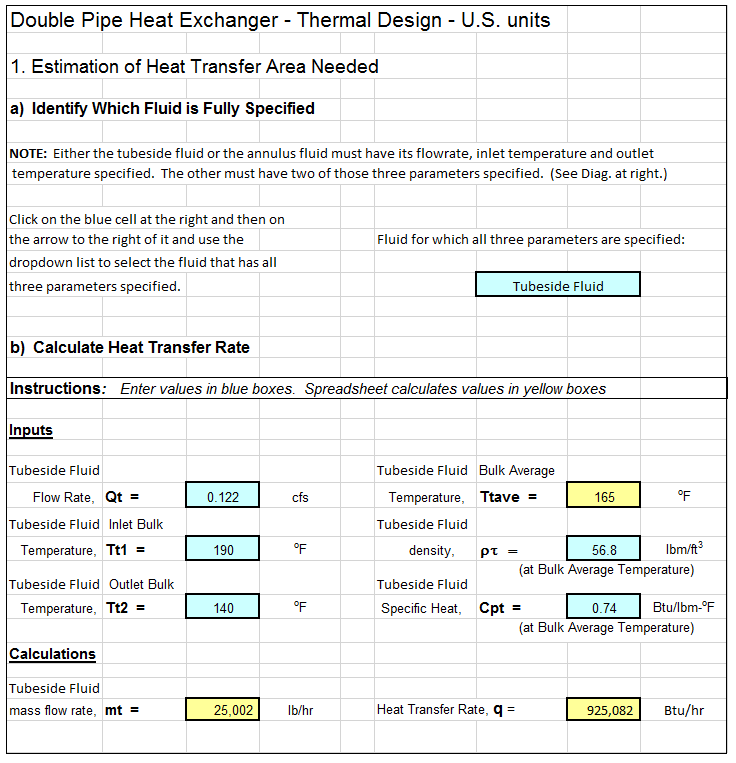

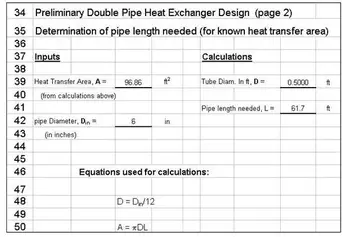

Units for double pipe and shell and tube heat exchanger design. Design calculate core length from cooling load. The pressure drop calculated for shell and tube heat exchangers is that.

4214 Tube-Side Heat Transfer Coefficient The heat transfer coefficient for the tube-side is. Excel spreadsheet templates can be downloaded in US. Pdhonline course m371 2 pdh shell and tube heat.

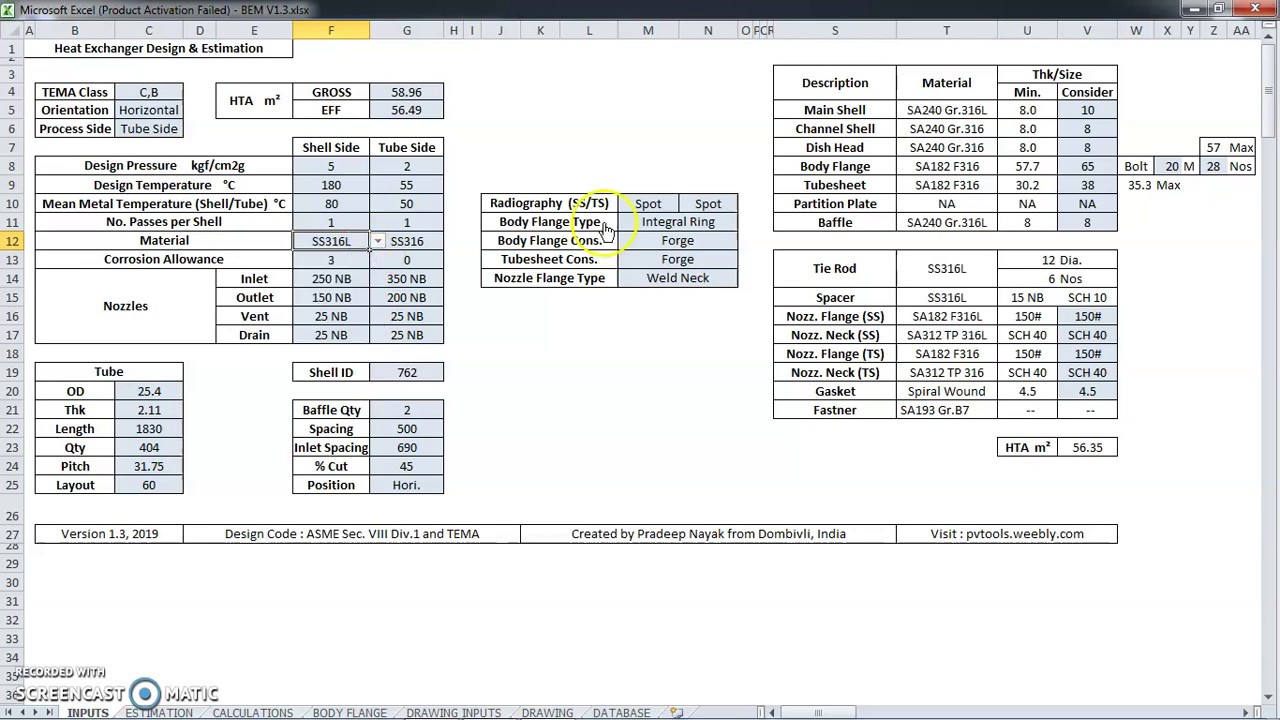

Air cooled heat exchanger design sizing calculations software. Use your local currency such as kg. Multi Heat Exchanger BEM Estimation Spreadsheet.

Shell side heat transfer coefficient. Shell and Tube Heat Exchanger Design Screenshot. This template calculates the size of an ST heat exchanger.

Shell and Tube Heat Exchanger BEM Design Estimation Spreadsheet. Shell and Tube Heat Exchanger BEU Design Estimation Spreadsheet Design Calculation of Parts Costing Dimensional Sketch of Body Flange Price. For more information please visit the Products page.

Download Shell and Tube Heat Exchanger Design for Windows to compute the design calculations of shell and tube heat exchanges. Choose a Model Number. Up to 10 cash back This Excel workbook presents formulae and data for.

- if you need a custom designed heat exchanger. The most common problems in heat exchanger design are rating and sizing. This is a simplified tube-shell heat exchanger design.

Input tubing OD BWG and length can be trial and error. April 29th 2019 - A Heat Exchanger Thermal Design Calculations Spreadsheet The screenshot below shows a heat exchanger thermal design calculations spreadsheet that can be used to carry out thermal design of a double pipe heat exchanger The image shows only the beginning of the calculations Heat Transfer Calculations AccessEngineering. Thermal Conductivity Fouling Resistance.

Shell and Tube Heat Exchanger Design software STHex. Duty Area Shell and Tube velocities Number of. SHELL TUBES Doc.

Welcome to klm technology group com engineering design. Select a Tube Side product fluid and Shell Side working fluid. Effectiveness and lmtd correction factor of the cross flow.

ENGINEERING CALCULATION Designed by Rey Fiedacan THERMAL CALCULATION OF HEAT EXCHANGER Date 11072010 TYPE. Setting shell side and tube side pressure drop design limits. The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can be summarized as follows.

This should be treated as a quick check for budgetary proposals only. Design A Shell Tube Heat Exchanger On Ms Excel - posted in Process Heat Transfer. Calculate the required heat transfer area based on values needed.

Physical properties of the most common fluids used in heat exchangers in Oil Gas Petroleum Refining and Chemical processes. I am new to this website I wanted to share a few spreadsheets dont know whether this where I should share the file or not. Unlike other tools ensures that the calculations are performed step by step to help in understanding the design calculations.

Version 14 Design Code. Enter the fluid Flow Rate Temperature and Pressure at the heat exchanger. Unknown exit temperatures on both sides or Unknown two Temperatures one shell side and another tube sides.

This is a sample of the Heat Exchanger Sizing CalculatorTo access the working calculator please sign up for free membership trial. A heat exchanger can be designed by the LMTD when. Download the Excel spreadsheet templates in this article to make preliminary heat exchanger design calculations.

STHex is a software tool that is made to demonstrate the chemical design rating calculations of Shell Tube Heat Exchangers. Free To Try 11999. Define process requirements for the new exchanger.

Select a suitable type of shell and tube exchanger. Shell-and-tube heat exchangers fitted with plain tube. Specifications In this project shell and tube heat exchanger is designed to heat 11443 kgs oil from 284 K to 318 K by cooling the water from 358 K to 326 K.

-1 input physical properties at bottom. Heat transfer coefficients U and α. Shell and Tube design and rating Tube vibration analysis Air Cooler design and rating Others Plate and frame plate-fin spiral plate hairpin jacketed pipe and fired heater etc.

DESIGN PROCEDURE OF SHELL AND TUBE HEAT EXCHANGER A. Frictional head loss and pressure drop calculations are done with the Excel formulas in the spreadsheet template using the Darcy Weisbach equation. Unknown Flow rate Unknown temperature on either shell or tube side can be calculated.

With shellside and tubeside inletoutlet temperatures fixed the required shellside flow is calculated corresponding to given tubeside flow. This is a calculator for sizing a shell and tube heat exchanger with tubeside flow fixed. They will also calculate the number of tubes needed for a shell and tube heat exchanger and to calculate the pipe length needed for a.

Heat exchanger theory calculations and design. In order to do this duty of process should be determined in accordance with cold fluid because properties of cold fluid are known. - to evaluate a Model Number not shown in the calculator.

ASME SecVIII Div1 and TEMA Design Calculation of Parts Costing Dimensional Sketch of Body Flange Drawing for Horizontal Position. Step by step design and rating calculations Support SI Units and English US Units of measurement Units converter is also included Save. Tube and fin material.

3000 INR 60 USD. Heat Capacity Heat Exchanged Av. Here attached is a Spreadsheet to Design a Shell Tube Heat Exchanger with minimum number of inputs and most of the work being.

HX - 01 -09 DEVELOPED USING EXCEL BY REY FIEDACANMECHANICAL ENGINEER 11072010 email protected Revision 1 21 Prandtl number 680236 22 Reynold number at tube side. Heat exchanger calculations and modeling to get the output. Shell and Tube Heat Exchanger Software Features STHex Step by step design and rating calculations.

Process fluid assignments to shell side or tube side. Define design parameters such as - number of tube passes tube size shell ID etc. And rapid calculation of shell-side coefficients and pressure drop to be carried out 72.

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

Preliminary Heat Exchanger Design

Download Shell And Tube Heat Exchanger Design 3 2 0

Excel Calculations Double Pipe Heat Exchanger

Heat Exchanger Thermal Design Calculations Spreadsheetlow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheets

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

Shell And Tube Heat Exchanger Bem Design Estimation Spreadsheet Updated Version V1 3 Youtube

Heat Exchanger Calculations And Design With Excel Spreadsheet Templates Bright Hub Engineering

0 komentar

Posting Komentar